Transforming the world with unrivaled IP and CNT technology.

Established in 2015, our vision is to develop and manufacture advanced materials that could significantly impact performance, cost and sustainability for global solutions. The world’s best carbon nanotube (CNT) technology combined with our unique ability to integrate nanotubes into worldchanging applications is what defines our company.

OUR MISSION

The CHASM mission is to develop and manufacture advanced carbon nano materials, leveraging our innovative product platforms to create a safer, more connected and sustainable world.

Strong IP and technology — it’s our unfair competitive advantage.

Putting nanotubes to work

- Novel CNT Hybrids that are better than either material alone

- Product solutions (dispersions, inks, films) that are easy to work with

Two product platforms

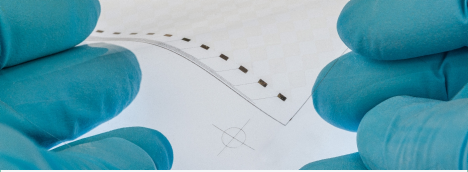

- AgeNT: Performance films for transparent antenna and heater applications

- NTeC: Performance additives for cement and EV battery applications

A deeply experienced team

- Founded by CNT industry leaders Dave Arthur & Bob Praino

- Experienced and committed leadership team and board of directors

OUR CORE VALUES

Act with integrity. It all starts here. We earn trust by giving our word, keeping our promises and always doing the right thing – even when it is uncomfortable and even when no one is looking.

Be curious, innovate. We take a relentless and creative approach to solving problems. Think big, look for opportunities to improve, ask for help, keep getting better every day, and NEVER give up.

Collaborate enthusiastically. We are stronger as a team. Our success will be built and sustained by sharing, working and learning with our colleagues, partners and customers.

Work with passion. We want to win... and have fun doing it. We are driven to dream big, do great work, make a difference, and go beyond expectations.

Make a positive impact. At CHASM we aim to contribute real value with every action we take and every interaction we have, and to approach that with purpose and humility.

Execute. Deliver. Own it. Deliver results. Take accountability. This is how we are building something great together.

CHASM Advanced Materials is a global product innovation company headquartered just outside of Boston in Canton, Massachusetts. The company’s seasoned team of scientists and engineers use nanotubes to manipulate materials for better performance – whether it’s extending battery life for harsh environments or developing advanced purification systems to address the global water crisis. The possibilities are endless when our team takes on a design challenge.

CHASM’s seasoned team of scientists and engineers, many of them working in CHASM’s R&D center in Oklahoma, use their proprietary processes to create substances at the nanoscale (a scale for measuring atoms and molecules) that, when mixed with certain elements, like carbon or graphite, unlock entirely new properties. These resulting “hybrid” or “advanced” materials are then applied in precise ways to make ordinary industrial and consumer products do extraordinary things.

.jpg)