Change the way you imagine your world.

CHASM helps to make consumer and industrial applications more useful, efficient and sustainable using our AgeNT Performance Films and our NTeC Performance Additive product solutions.

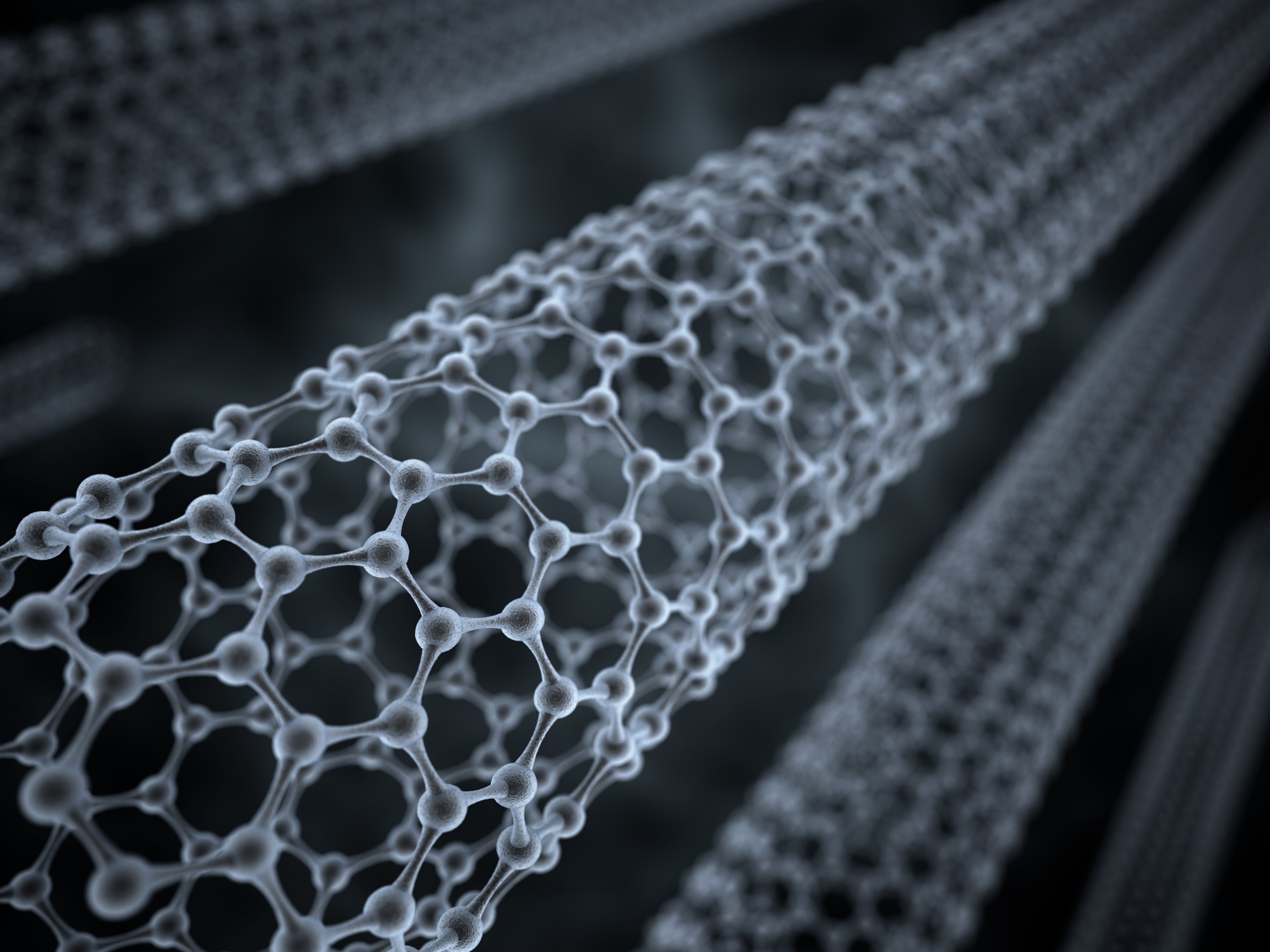

Explore what Carbon Nanotube and Carbon Nanotube Hybrid solutions from CHASM can do and why we believe small changes can have big impacts.

A new weapon in your problem-solving arsenal.

CHASM creates advanced nanotube hybrid materials that help product manufacturers deliver breakthrough product performance enabling critical product differentiation and business growth.

A nanotube hybrid is the deliberate combination of carbon nanotubes and another element such as carbon, graphite, silver or copper to unlock entirely new properties and performance characteristics. CHASM uses proprietary processes to create nanotube hybrids from their industry leading single wall carbon nanotubes. Manufactured in the USA, the resulting nanotube hybrids are applied in precise ways to make ordinary industrial and consumer products do extraordinary things.

For example, when added to batteries, nanotube hybrids make them last significantly longer and charge faster, even in harsh environments. When used for printed electronics, nanotube hybrids enable product designers and engineers to create transparent and flexible 5G antennas that can be seamlessly added to lights or windows or heaters that can be layered across an automobile windshield, headlight or ADAS sensor for optimal safety and performance in varying environmental conditions.

.png)

AgeNT

CHASM's AgeNT performance films are transparent conductive films that are flexible and formable with low patterning costs and superior optoelectronic performance of low sheet resistance at high transparency. Leading companies across multiple industries have successfully launched their next generation innovations using transparent heaters, antennas, and EMI shielding films made from advanced Nanotube Hybrid materials only available from CHASM.

%20(1).png)

NTEC

CHASM's NTeC performance additives, utilizing CHASM's highly scalable CNT production platform, are affordable, safe to handle and deliver the highest possible performance. Our carbon nanotube and carbon nanotube hybrid products are developed in collaboration with industry partners for specific applications, like batteries and construction materials (cement and concrete). Dramatic improvements to material properties are possible with nanotechnology. Find out how NTeC can take your products to the next level!

SIGNIS

CHASM's best in class Signis™ Carbon Nanotubes have been engineered to satisfy not only the requirements of specific advanced materials applications, but also to be adaptable to a variety of manufacturing technologies. produced using our patented CoMoCAT™ synthesis process results in CNTs that are semiconducting or conductive due to our ability to vary and control chirality and tube diameter.

.jpg)