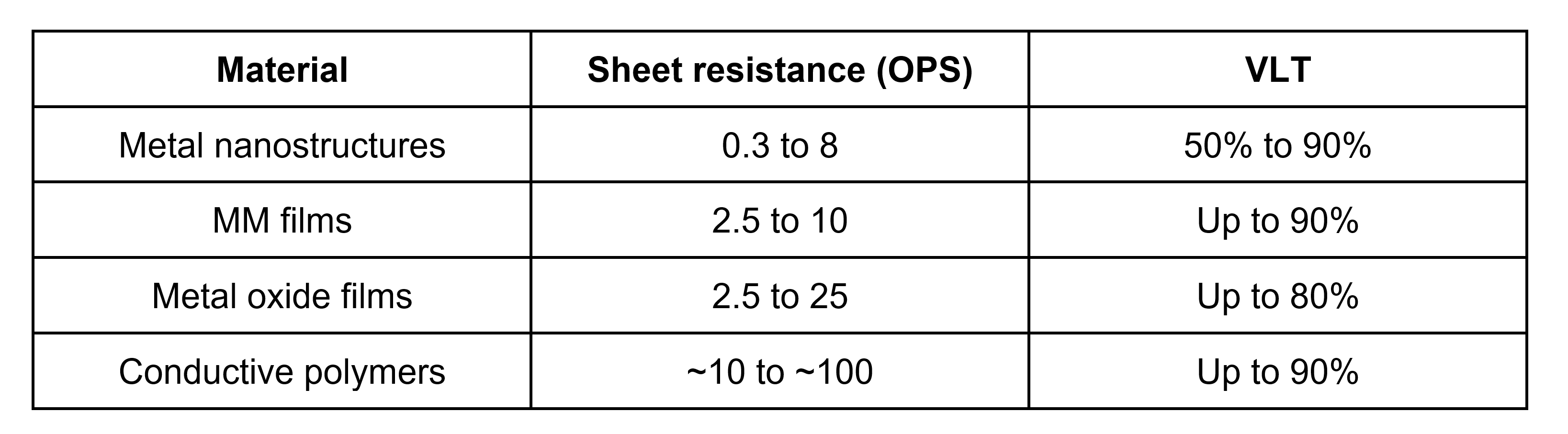

Although not particularly new, the variety of flexible TCFs reported in the literature and on the market is extensive, and many materials have been specialized for different products. The current range of flexible TCFs includes metal oxides, conductive polymers, metal nanostructures, and MMs.

While these materials can be fabricated on a flexible substrate like PET, they all carry some common disadvantages that inhibit scalable manufacturing or their use as high efficiency antenna materials in high-GHz RF products. The primary design requirements for commercializable flexible TCFs as antenna materials are:

- Low sheet resistance: Designers that want flexible TCFs for antennas need a material with sheet resistance not greater than 1 OPS.

- High VLT and low haze: Transparent conductors should be nearly invisible (at least 90% VLT) and have less than 5% haze.

- Simple manufacturing process: The fabrication process for an ideal flexible TCF should be easy to scale and carry low costs. The number of deposition, curing, etching, and cleaning steps should be minimized.

- Patterning over a large area: A larger has a larger absorption cross section for detecting low-level signals. A flexible TCF antenna should be scalable up to any desired size with patterned geometry.

Metal nanostructures

Metal nanostructures satisfy the first design requirement listed above, but they have significant haze and are translucent with low VLT in the visible range. They are also costly to manufacture on transparent flexible substrates at the scale needed for their envisioned applications, requiring processes like photolithography for substrate patterning, followed by sputtering, solution growth, or vapor deposition.

MM Films

MMs are similarly un-promising as GHz antenna materials thanks to their sheet resistance of at least ~3 OPS. These materials can be nearly invisible as long as the mesh size is less than ~6 microns, but fabricating this pattern requires an electroless copper process or photolithography process, both of which are followed by etching.

Patterned Transparent Metal Oxide Films

Other materials, such as metal oxide TCFs, only satisfy the fourth design requirement. Getting sheet resistance below 2.5 OPS is a major challenge, making these materials unsuitable for use as high-efficiency antennas. The morphology of these materials makes them hazy with insufficient VLT (up to ~80%) for antenna applications. The patterning process for metal oxide TCFs is inefficient in that it requires a subtractive process, or it requires direct pattern deposition with a photolithographic process. Using photolithography allows the desired conductor pattern to be deposited directly on the substrate, but it requires multiple develop, etch, strip, and cleaning steps, just as is the case with MMs. Laser ablation is also useful for patterning on glass, but it can damage a flexible plastic or polymer substrate. This process also requires significant laser time, which increases overall patterning costs.

Conductive Polymers

Conductive polymers run the gamut on satisfying these requirements. Ag nanowires mixed with PEDOT:PSS (a popular TCF) provides very high transparency, but its sheet resistance is much too large for use as an antenna. It remains to be seen whether a conductive polymer TCF material with high VLT can be found and produced at scale.

Finding Alternative Materials

Obviously, it has been difficult to find materials that can satisfy all the above requirements. A clear alternative is a hybrid material that provides the high transparency of an open MM with low sheet resistance and fewer manufacturing steps. A new class of printable carbon nanotube hybrid materials offers a solution to this unique set of problems and will enable a new class of IoT, 5G, and automotive radar devices with flexible transparent printed antennas. Learn more about 1 ohm/sq flexible TCFs with low haze here.

Looking to learn more? Download the guide:

.jpg)