Transparent Heaters for Applications Requiring Optical Transparency

3 Ways to Find Transparent Heaters for Applications Requiring Optical Transparency

There are many applications in today’s manufacturing world that require an optically clear transparent heater. The automotive or transportation industries require transparent heaters to ensure safety systems remain online and security systems remain active. Retail and grocery stores require ways to keep refrigerated display cases from fogging so the contents remain visible to shoppers. Whatever the case, a project that requires an optically clear transparent heater can be a tall order due to the short comings of the few available, well known transparent and conductive materials.

1. How Is a Transparent Electric Heating Film Generally Used?

A transparent electric heating film is typically constructed by "sandwiching" a conductive material between layers of glass or clear plastic such as polycarbonate or acrylic. The challenge here is deploying a conductive material that has both sufficient conductivity AND transparency.

One example of an application requiring a transparent conductive material was the project of a client in the automotive industry. The client required a transparent conductive material that could be used to design a heater that would perform even to their minimum design temperature of -40° F. Since the heater was to be embedded in a 3D sculpted surface, they also needed this transparent conductive material to be molded or thermoformed and required enough transparency to prevent interference with the operation of the sensors and lighting.

Get the Guide: Transparent Heaters for Product Design - The Ultimate Guide

2. What Materials Excel in Applications Like This?

If you’ve used materials in the past such as PEDOT or ITO, you know that they are excellent materials for certain applications but not all. In an application like the once described above, these materials (PEDOT and ITO) are simply not feasible. For example, ITO is not flexible and cannot be formed or molded. PEDOT is flexible but it struggles with environmental stability and optoelectrical performance. So how did this client solve the problem? CNT Hybrids.

3. New Materials

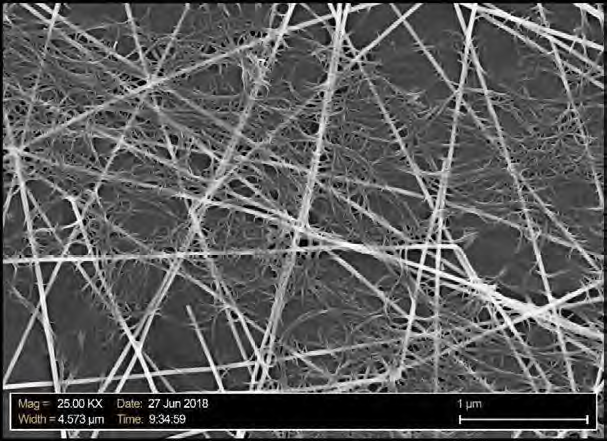

CNT Hybrids are a patented combination of silver nanowire (AgNW) and Carbon Nanotubes (CNTs) that serve as an ideal ITO alternative. The unique combination provides flexibility and environmental stability plus it can perform at <10 ohms/square with greater than 90% visible light transparency – ideal for transparent heater applications requiring optical transparency. Another critical attribute that CNT hybrids deliver is redundancy in conductive pathways. With CNT Hybrids the AgNW is encapsulated in highly conductive CNTs, allowing the material to offer a redundancy in conductivity if the AgNW suffers from any discontinuities or breakage. In applications where keeping a surface clear of ice or fog is critical, having this redundancy can mean the different between success and utter defeat.

.jpg)