Nanotube-AgNW Hybrid Films

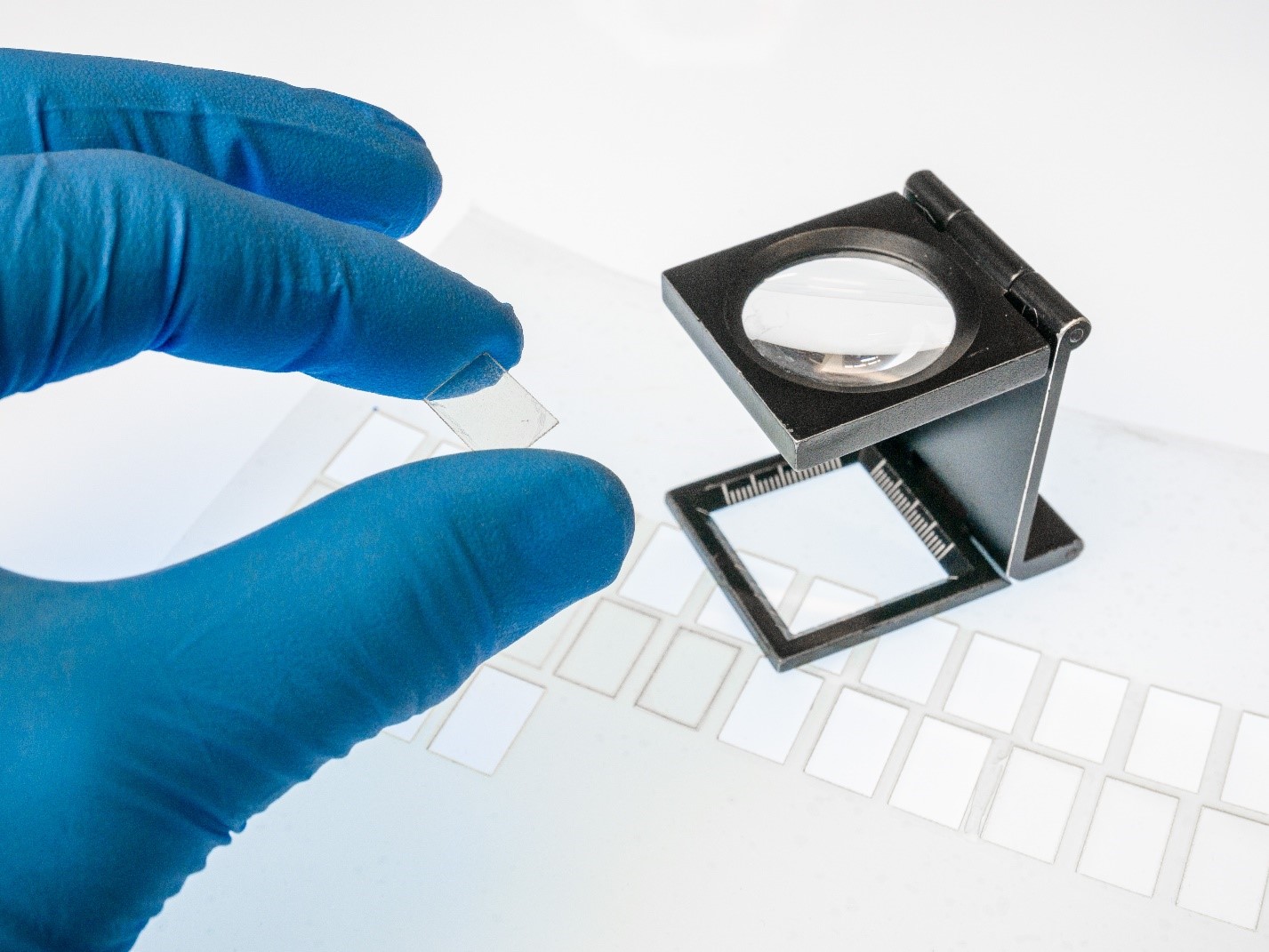

Another commercially available formulation for nanotube hybrid shielding films utilizes a transparent conductive substrate comprised of silver nanowire (AgNW) encapsulated with a functionalized nanotube coating. Being environmentally stable, the nanotube coating not only protects the AgNW network from moisture, humidity, and abrasion, but also creates a nanoscale conductive shield network. Effectively a nanoscale faraday cage, higher frequency waves are suppressed. Highly transparent and easily patterned to any shape, the AgNW nanotube hybrid is an ideal candidate for applications where shielding of LCD screens, user interface buttons, enclosure windows, lighted status indicators, or operational status monitors is required while not negatively impacting their individual visibility.

Applying an optically clear adhesive, nanotube hybrid shielding films can be selectively applied with "peel & stick" ease. And measuring under 10-mils in thickness, nanotube hybrid shielding films require little space even in existing applications having minimal clearance envelope so can be added inside existing housings or enclosures without redesign.

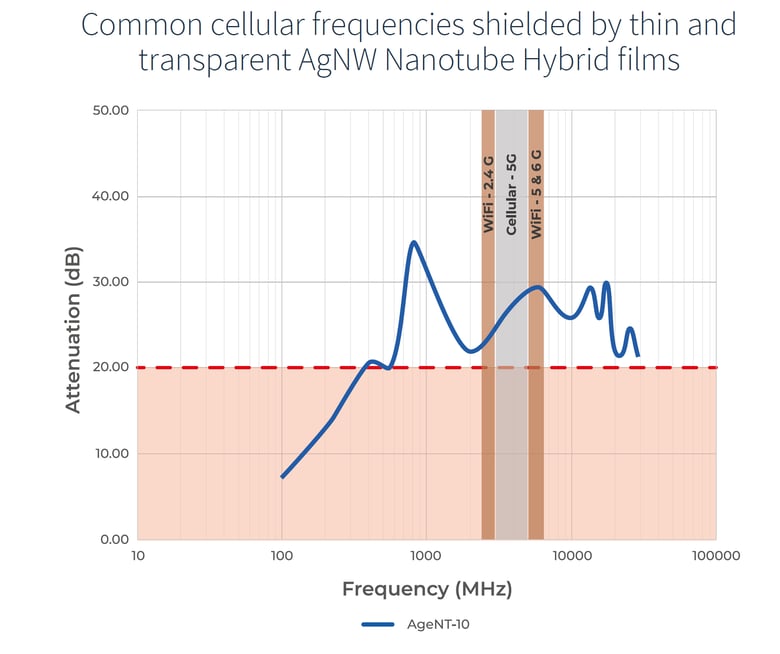

While not delivering as universal protection as demonstrated by the MM nanotube hybrid, the AgNW nanotube hybrid can still deliver effective protection in select applications. Providing effective shielding above 20dB particularly across the predominant WiFi and cellular frequencies including 2G and 5G as shown in the figure above, AgeNT-10 provides ample protection for smartphones, tablets, or any electronic device using standard wireless connectivity signals.

Flexibility, Economy, and Agility of Fabrication

Traditionally fabricated from metal sheets formed to fit the intended enclosure, plated steel, copper and silver alloys, and aluminum have been staple materials for EMI shielding. Designing these shield enclosures must take into consideration necessary clearance envelopes to avoid interference with other components inside the device enclosure. Conductive plastics in tape, film, or foil form have also emerged as effective for anti-static applications, but have not reached widespread adoption with respect to shielding RF frequencies. While fabrication methods for metal sheets are mature and pervasive, tooling such as brakes, presses, punches and sheers require sizable capital investments and are single purpose. Completing all the multiple requisite steps to fabricate metal shields in sequence also takes days – if not weeks – to successfully complete.

Alternatively, EMI shielding created using nanotube hybrid films can be quickly and efficiently fabricated using low-cost screen printing for patterning, offering significant savings in manufacturing costs, processing time, and reduced risk of scrap. Creating EMI shield patches or circuits from nanotube hybrids is simply print, etch, and done. For applications requiring ground plane connection, screen printing conductive silver busbars onto the film makes them integral to the shield simplifying mass production. And since nanotube hybrid shielding films utilize a thin, flexible plastic substrate, they can be flexed, folded, or formed for easy incorporation into existing enclosure with limited space and small form factors.

Another advantage of nanotube hybrid materials is the capability of providing sufficient shielding effectiveness for the desired application without requiring a perimeter ground. While creating a perimeter ground connection is typically done using printed silver to insure maximum shielding effectiveness, select applications can be well-served without connecting to a ground plane. For small aperture applications or those requiring attenuation of just single digits, nanotube hybrid films alone can be quite effective and easily retrofitted using "peel & stick" optically clear adhesive.

Conclusion

Whether utilizing a metal mesh or a silver nanowire substrate, the conductive redundancy and unique RF interaction properties of CNTs make nanotube hybrid shielding films far superior to the base materials alone. Flexible and formable, nanotube hybrid shielding films deliver an easily adaptable platform for introducing RFI/EMI shielding solutions in both new or existing electronic assemblies. Simple and cost-effective to produce at manufacturing scale, universally available screen printing produces desired patterned configurations as simple as "print, tech, done". Whether in new applications or as a retrofit, nanotube hybrid films give engineers an easy to execute method of adding RFI/EMI shielding capabilities to new or existing electronics assemblies, providing higher SE values than existing solutions without compromising on transparency.

Increasingly sophisticated and delivering mission critical operation, electronic systems are pervasive in nearly all of our day-to-day activities. From keeping us connected to each other through an increasing array of smart devices, to ensuring safe operation of our vehicles when commuting – especially when distracted – to delivering real-time medical diagnostic information around the globe enabling doctors in one country to treat patients in another, all depending upon wireless connections of increasing density, ensuring uninterrupted operation without interference can easily be a matter of life and death. EMI shielding provides an effective mechanism to control exposure, but traditional materials and methods do not deliver the effectivity and flexibility needed for future applications. Transparent, flexible, formable, and effective at pervasive wireless RF frequencies, nanotube hybrid shielding films offer versatility at shielding applications previously considered impossible. Proven superior in protection to even copper foil, nanotube hybrid shielding films transparently protect even in touchscreen, window, button, or other apertures in electronic devices.

%20EMIRF%20Shielding.png?width=222&name=(WHITEPAPER)%20EMIRF%20Shielding.png)

Download the Whitepaper:

Clearly Superior - Transparent RFI/EMI Shielding Outperforming Copper Foil

.jpg)